Raw Hides/Skin:In order to prevent bacterial activity, the moisture content should be brought down to less than 30%. This dehydration is usually done by applying common salt (i.e., Sodium Chloride) to hides/ skins to the tune of 30-45% by weight.

Sorting:Hides and skins are sorted into several grades by size, weight, or quality.

Trimming:Trimming is generally carried out during the sorting process. Some of the edges (legs, tails and heads, etc.) of raw hides and skins can be cut off. Usually this is done in the abattoir, but it can also be carried out in tanneries.

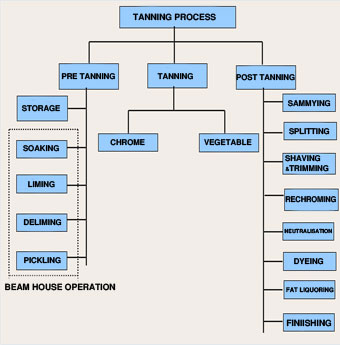

Curing and storing:Curing is a process that prevents the decomposition of hides and skins from the time they are flayed in the abattoir until the processes in the beam house begins. Whenever a raw material cannot be processed immediately ("green"), it must be cured. Popular methods of long-term preservation are salting and drying. Methods for short-term preservation (2- 5 days) are cooling, using crushed ice or refrigerated storage, and biocides. Curing is done in the abattoir, at the hide market, or at the tannery. In certain cases it might be necessary to repeat the step in the tannery, e.g., chilled hides can be salted for longer storage, if salting was not efficient enough. Hides and skins are generally stored on pallets in ventilated or air- conditioned and/or cooled areas, depending on the method of curing chosen. From storage, the hides and skins are taken to the beam house.

Soaking:The main purpose of this process is to remove salt used during curing, re-hydrating the material and to getting rid of unwanted materials such as dung, blood, soil, etc. The duration of soaking may range from several hours to a few days. Depending on the type of raw materials used, soaking additives such as surfactants, enzyme preparations and bactericides can be used.The process of soaking can be classified into three stages:

Dirt Soaking-In dirt soaking, 300-400 % of water is used to remove the unwanted materials

Main Soaking-The purpose of main soaking is to re-hydrate the material. In this operation, water, non-anionic wetting agent (0.2% concentrated Soda ash (0.2% concentrated) and preservatives (0.0 5% concentration) are used.

Final soaking-Only water is used for the washing purpose in this operation. Major part of salt associated with preservation of skin/ hides is removed during the soaking operation.

Liming:The purpose of this operation is to facilitate the removal of hair, flesh, fat (partially), inter-fibrillary protein and to open-up the fibrous structure for osmotic swelling. The process of liming can be broadly classified into two parts i.e., dehairing and re-liming

Dehairing–Lime (8-10 %) along with Sodium Sulphide (3 %) is applied to the skin to remove hair

Re-liming–To open up fibrous structure, lime, soda ash, caustic soda, etc., are applied. The pH of the skin being processed will rise to 12- 12.5.

Fleshing:The excess fleshing is removed manually or by using fleshing machines. The quantity of wet fleshings is in the range of 10-15% of the weight of raw hides/skins

De–liming:This is a process to adjust the pH between 8-8.5 in order to enhance the enzymatic activity, which converts some of the proteins into soluble forms. pH correction i.e., from 12-12.5 to 8-8.5 are done by using ammonium chloride in case of soft leather and ammonium sulphate in case of hard leather.

Pickling:Pickling is a process of correcting the pH suitable to the tanning operation and to prevent swelling of the leather i.e. dehydration of the leather. In this process, water (80%), salts (8-10%), formic acid (0.28- 0.3%), sulphuric acid (0.75 – 2% based on thickness) are applied.

Ph correction:for vegetable tanning, a pH between 4 and 4.5 is maintained whereas, pH between 2.5 and 7.3 is maintained in case of chrome tanning. Prevention of swelling: salts to the tune of 8-10% are used in this process to prevent swelling. |